l'm back Camera

Our Service : Industry Design, Mechanical Design, Prototype, Production

In a design studio full of creativity and passion, the design journey of a new camera quietly began. This is not only a tool for capturing light and shadow, but also the fruit of the hard work of craftsmen. It is a product that perfectly integrates art and technology. Let’s take you through the entire process of building this camera.

1. Appearance design

The appearance of a camera is not only about its beauty, but also about the user’s feel, ease of operation and intuitive feeling of beauty. After countless modifications and improvements, our team finally completed a prototype of an exterior design with smooth lines, simplicity and modernity.

2. Structural design

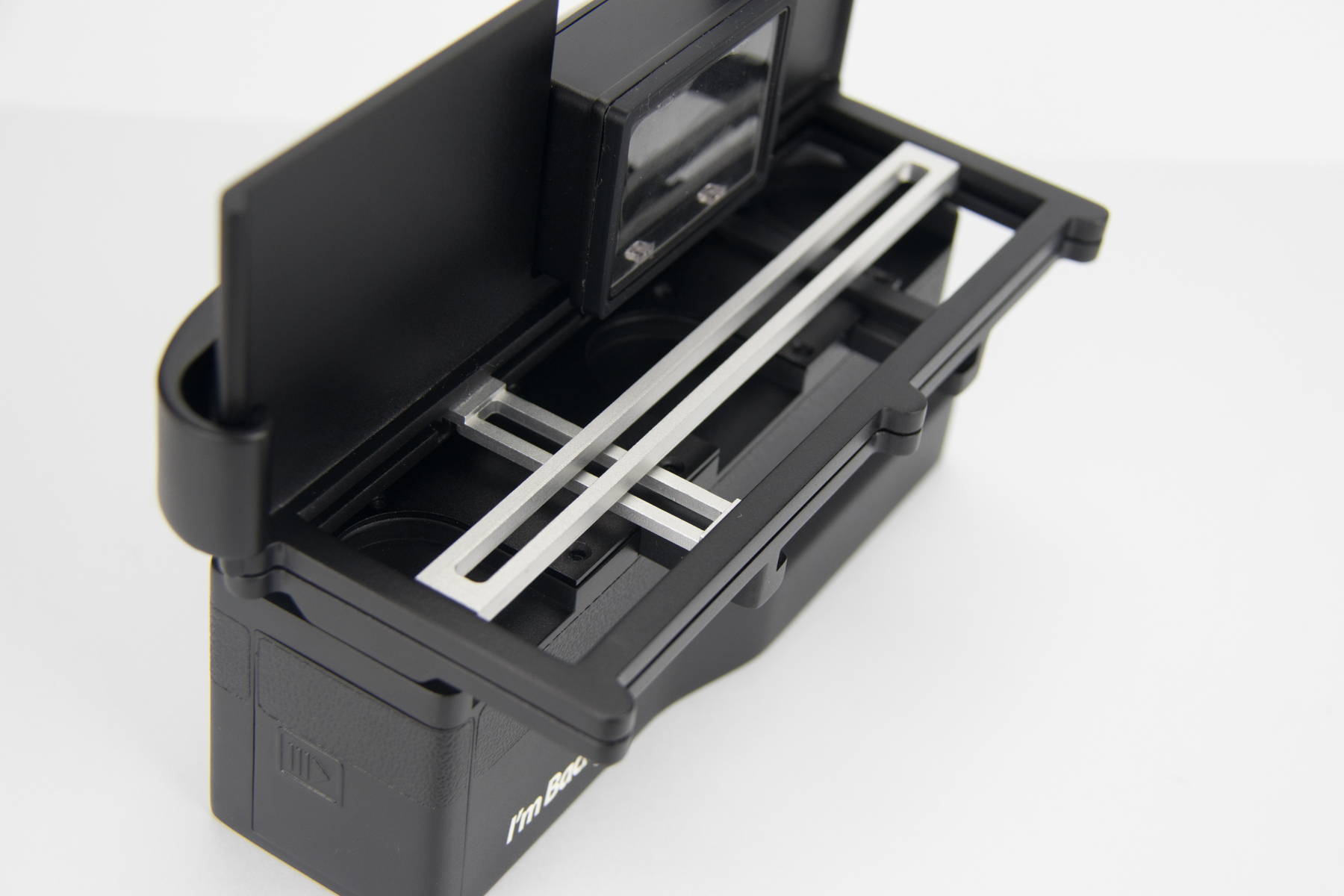

The internal structure of the camera is complex and precise. The position and size of the lens, sensor, shutter, battery compartment... each component requires careful calculation and simulation.

3. Prototype production

After the design drawing was finalized, we started prototype production, which is a process of converting two-dimensional drawings into three-dimensional entities. Through high-precision CNC machine tools, pieces of material are accurately cut and polished, and finally spliced into a complete prototype model. Then touch every detail with your hands to achieve a comfortable feel, which also provides a valuable physical reference for subsequent mold opening and injection molding.

4. Mold making and injection

After the prototype is completed, the mold opening and injection molding stage is entered. The mold master carefully carves every detail of the mold based on the camera prototype. Subsequently, the liquid plastic is injected into the mold and gradually solidifies under high temperature and pressure.